Synovial joint as a model for the development of super-lubricated surface-attached hydrogels

Tribological contacts account for about 23% of worldwide energy consumption. While 20% of this energy is used to overcome friction, the 3% repair wear failures. Consequently, friction and wear cause costs of 250 billion euros every year and they are responsible for the emission of 8120 Mt of CO2 [1]. This problem can be solved by creating materials that exhibit low friction, preventing the wear phenomena and minimizing energy loss.

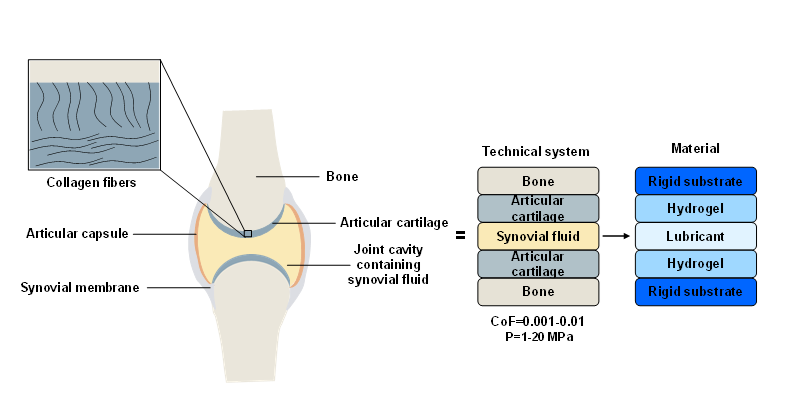

Despite using oil-based lubricants, whose recycling is only partially possible, natural systems can be an inspiration for developing technical systems because of their high efficiency, durability, and ability to adapt themselves to new environmental situations. The evolutionary process has led to specialized surfaces where friction is adjusted to meet the requirement of the living organism for different purposes, for example, the synovial joint of mammals, in which the synovial fluid plays a crucial role as a water-based lubricant [2].

In this context, hydrogels are promising materials because they consist of a solid matrix, which can recover their initial shape after stress release, and have a high-water content, similar to biological tissues.

This work aims to investigate the impressive frictional properties of bio-inspired hydrogels covalently attached to a rigid substrate by C,H-Insertion Crosslinking (CHic) via UV radiation. CHic is a method in which crosslinking and covalent attachment to the substrate occur simultaneously, as reactive groups are incorporated into polymer chains by a copolymerization reaction [3]. Moreover, it is important to investigate the role of the indenter geometry on the mechanical properties of these materials. When the surface-attached hydrogel is compressed, the polymer network undergoes conformational transitions between compressed and stretched chains and this is strongly dependent on the shape and size of the slider. As a consequence, a change in the geometry of the slider (spheres of different radii, pyramid) might lead to a different mechanical response.

The figure is illustrating the fundamental challenge of this project. Inspiration from nature (synovial joint) leads to create new surface-attached hydrogels for CHic reaction. The final goal is to get super-lubricated surface materials for any type of application.

References:

[1] Holmberg, K., Siilasto, R., Laitinen, T., Andersson, P., Jäsberg, A. (2013), Global energy consumption due to friction in paper machines, Tribology International, 62, 58-77.

[2] Mow, V. C., Ateschian, G. A., Spilker, R. L. (1993), Biomechanics of Diarthrodial Joints: A Review of Twenty Years of Progress, J. Biomech. Eng., 115, 460-467.

[3] Prucker, O., Naumann, C. A., Rühe J. (1999), Photochemical Attachment of Polymer Films to Solid Surfaces via Monolayers of Benzophenone Derivatives Photochemical Attachment of Polymer Films to Solid Surfaces via Monolayers of Benzophenone Derivatives. J. Am. Chem., 121, 38, 8766–8770.