Hairy situation solved with new fabrication technique

A recent article from CPI Alum, Stefan Müllers, details a new technique for fabricating artificial hairy surfaces made from polymer materials.

When it comes to animals (and even some plants) hair can be found anywhere and everywhere. And thankfully so, because hair helps perform a variety of vital functions– from UV protection, insulation, temperature regulation and even transport of liquids or for swimming.

Not only are these hairs often widespread – but they are many. Hair is often layered, forming a dense “lawn”– with the distance between hairs being significantly smaller than the length of any individual hair. This means hair carries a rather high aspect ratio.

This high aspect ratio, while biologically beneficial, makes it challenging to produce artificial hairy materials with polymer materials.

Müller et al. address this challenge and present a new technique for fabricating surfaces covered with a dense lawn of high AR nanoscale polymer hairs.

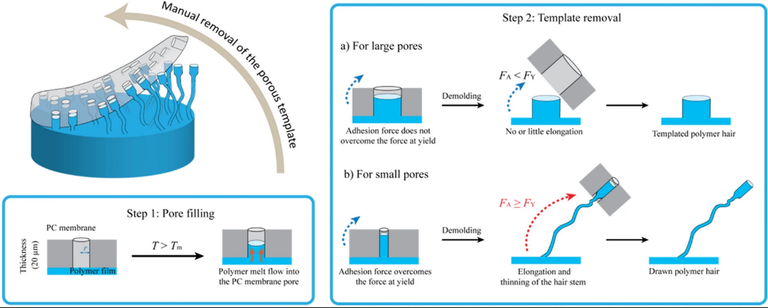

Pore-assisted modifications of polymer film surfaces using ion-track etched PC membranes as porous templates. Depending on the pore size either (a) microreplicated cylinders or (b) drawn hair-like nano- and microstructures can be generated.

Ultimately, Müller et al. demonstrate how their technique offers a relatively simple and time effective solution for creating unique topographies---Topographies which could dramatically tailor the wetting properties of common polymers.

The full article can be read on nature.com (open access).